The CMES Random Mixed

Depalletizing Application

Powered by AI, CMES Robotics 3D Vision provides the depth, angle, and data needed to guide a robot in more complex tasks. Our system enables robots to recognize unstructured, flexible, deformed objects, and deliver a reliable solution from Mixed Case Palletizing to Random Mixed Depalletizing.

RANDOM MIXED DEPALLETIZATION VIDEOS

Random Depalletizer

Mixed Case Palletizer

Powered by

ADVANTAGES

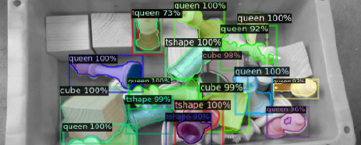

AI-Based Vision Recognition

With AI vision, the target detection of artificial intelligence “eyes” is becoming an important factor that can provide the machine the ability to detect and recognize contents in the warehouse logistic environment. CMES offers a software solution that makes it possible to detect and register random boxes.

3D Point Cloud Processing

Reduces interference from surrounding

objects by extrapolating only the

information from the 3D scanned data

required for box recognition. Additionally,

it is possible to extract the precise

location of the box and lower the

likelihood of inaccurate box identification

or non-detection utilizing 3D depth

information.

Continuous Detection

In the event of rare incorrect detection, the AI vision will continuously scan and learn the characteristic of the object to determine the placement and further improve the recognition accuracy and efficiency.

Collision Avoidance

By implementing a 3D simulation environment, it is easy to check current equipment status, box detection, and robot path and calibration results. In addition, the real-time vision and sensors will control the movement of the robot giving it instant collision-avoidance capabilities.